- Máquina de Vacío

- Envasadora Vertical

- Formadora

- Robot paletizador

- Máquina de Etiquetar

- Retractilado Empaquetado

- Sellador de Cartón

- Maquinas Flejadoras

- Flejadoras de Mano con Batería

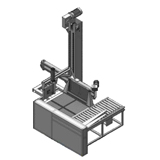

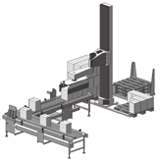

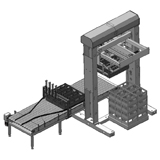

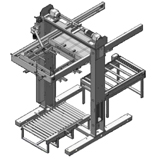

- Paletizador

- Máquina Empaquetado

- Cartón Empacador

- Línea de Embalaje

- Flejes de PP

- Film de LLDPE Stretch

- Rollo de Entrega

- Máquinas llenadoras

- Estuchadoras

0086-571-87978016

0086-571-87978016 info@youngsunpack.com

info@youngsunpack.com

Palletizers are machines that place goods on pallets in an orderly fashion. They come in many different configurations to handle a multitude of different packaging, incoming material lines, and automation requirements. Specific palletizers are available to handle bags, pails, drums, crates, cases, and kegs, etc. Many of these devices are configured to handle more than one package style.According to the servey,Commercial palletizers are available as fully automatic and semi-automatic devices. Fully automatic machines perform their function without operator intervention.

Palletizers are available in a number of different function configurations, differentiated by the manner in which they receive goods to place on a pallet. The three most common configurations are low level, high level and robotic. Low level palletizers are feed at ground level, while high level devices receive product through a hopper from above. In both cases, product may be received in a rolling or flowing fashion and continuously transferred to pallets. These types of palletizers are best used in applications where packing and shipping speed are important. However, they may be inadequate in situations where the product being shipped is fragile. In such cases, robotic palletizer should be used. These devices pick up, orient, and place materials onto a pallet one at a time. While slower, they tend to apply less stress to the materials while transferring them to a pallet.

| XD-25P Bottle unloader | |

| Power | 380V 50Hz 9KW |

| Air pressure | 3-6kg/cm2 |

| Working speed | 25000bottle/hours |